|

Web www.pumpfundamentals.com |

|

Web www.pumpfundamentals.com |

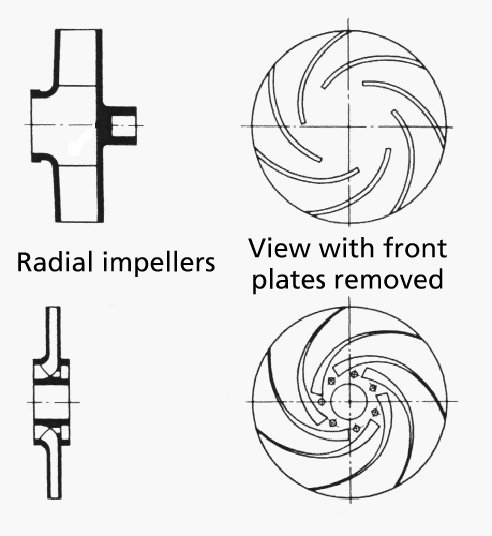

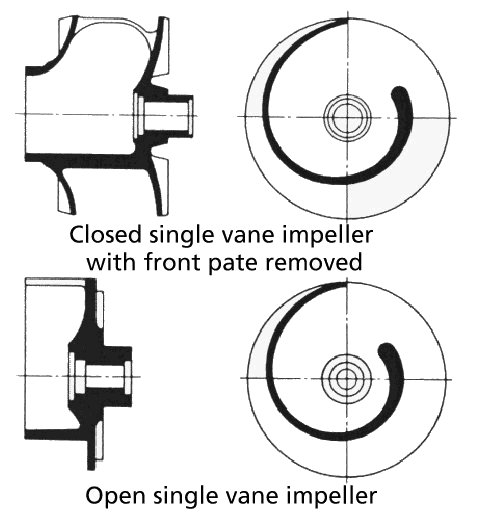

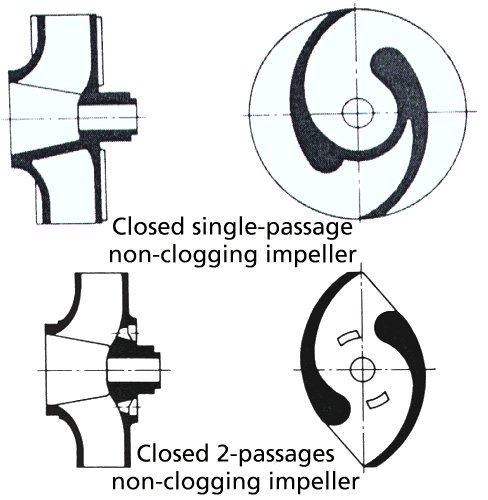

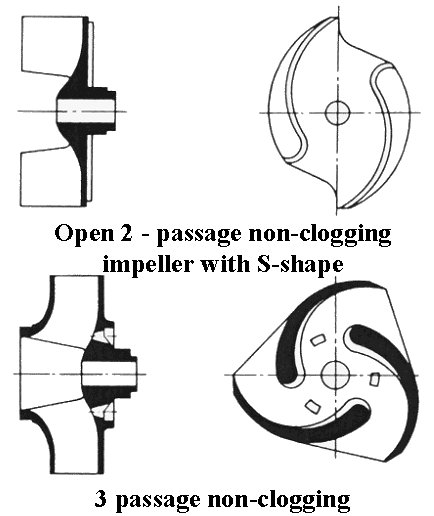

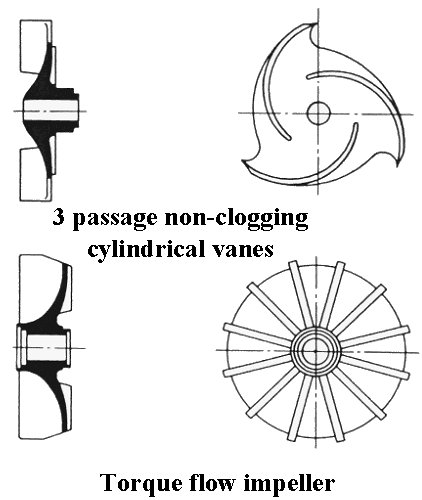

Impeller types can be radial, mixed flow, axial and peripheral and are selected on the basis of the pump design and the application.

The number of vanes will affect the efficiency, in general more vanes are more efficient. Also the number of vanes affect the steepness of the characteristic curve, see centrifugal pump tips for a graph on this effect.

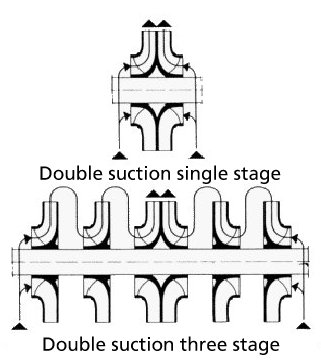

An impeller with a high number of vanes reduces the amplitude of the pressure pulses that are caused as the impeller tip passes by the cutwater. In certain applications these pressure pulses are undesirable such as a paper machine headbox pump which typically will be a double suction type with 8 or more vanes. The headbox is a large specialized nozzle that feeds a continuous stream of low consistency pulp on a traveling wire mesh which after drying produces a wide paper web. If the pressure pulses are too high compared to the average there will be a variation in the paper density which may affect printing quality and other operational factors.

|

|

|

|

|

|

|

|