NPSHA TUTORIAL

January 6, 2006

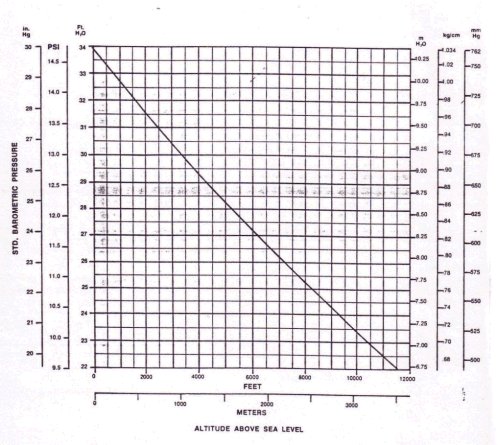

NPSHA for those who hate that stuffy word The dreaded term NPSHA means Net Positive Suction Head Available. It`s a term that most people find difficult to relate to in part because they have no idea what value it should have. Before we discuss values and the exact definition of NPSHA, let`s get an intuitive understanding of NPSHA. NPSHA is a measure that corresponds to the level of pressure at the pump suction. The higher the pressure, the higher the NPSHA and the better the pump will operate. Normally we measure pressure with a gauge that is calibrated in psig (pound per square inch gauge) or kPa in the metric system. This pressure scale is set at zero when there is no pressure or the pressure is equal to atmospheric pressure. The atmospheric pressure at sea level as measured on an absolute scale such as psia (pounds per square inch absolute) is 14.7 psia. In the absolute scale, pressure starts at zero which is the lowest possible pressure and means that there is no molecules of matter in the environment that can create pressure such as in outer space. It then can have any value corresponding to a high pressure environment. The term head in NPSHA has been well explained in the pump tutorial, the head component that we are most interested in here is the static head or the level of fluid above the pump suction. Head is measured in feet in North America and in meters just about everywhere else. The value of NPSHA will vary between the lowest value of 0 feet, up to the value of the local atmospheric pressure head 34 feet plus the suction static head minus a small quantity which we will get to shortly. 34 feet is the value of atmospheric pressure at sea level expressed in terms of pressure head. If your tank has 10 feet of suction head, the NPSHA may be 34 + 10 = 44 feet which is ample. One should start to worry when the value of NPSHA falls below 20 feet. How can the value of NPSHA drop below 34 feet? This is possible if there is allot of friction or plugging which increases friction in the suction line. Sometimes these two occur together, when the level is low in the suction tank due to physical constraints or poor level control or other reasons, this decreases the overall NPSHA and a further decrease occurs due to friction. How will you know if the NPSHA is adequate? The manufacturer tests the pump under various suction head conditions and provides a requirement or NPSHR for each flow condition on the characteristic curve of the pump. It is then a matter of checking this value against the NPSH available and making sure that the NPSHA is higher. Why do you have to worry about atmospheric pressure, after all atmospheric pressure is everywhere, how could the operation of the pump be influenced by its value? Because atmospheric pressure depends on the elevation, the pressure varies significantly depending on the elevation above sea level. Atmospheric pressure gets added to the pressure provided by the static head and if you are at a high elevation atmospheric pressure will be less and therefore the suction pressure will be less. OK, so let's say that the suction tank is pressurized with a nitrogen blanket on top of the liquid surface at 100 psig for example, do you still have to account for the atmospheric presure? Yes, you do. When you pressurize the tank you start pressurizing from some level, that level is the local atmospheric pressure. If your local atmospheric pressure is 10 psia and you add 100 psia of nitrogen pressure than your total on top of the liquid is 110 psia.

Figure 1 To measure suction pressure two units are typically used, the psia or pounds per square inch absolute or the inch of mercury. Pressure gauges can be purchased that have scales with either one of these two units in North America. The following figure shows how these two scales can be used.

Figure 2 |

|||

|

|

|||

Most pumps can operate with a suction pressure that is below atmospheric pressure. A pressure that is below atmospheric

pressure is referred to as a vacuum. That is why a value of 20 feet for NPSHA can be quite acceptable. This is also how it is

possible for a normal centrifugal pump to lift fluid from an elevation that is below the suction.

For more information on low

pressure at the pump suction see the pump tutorial.

Figure 3 A pump that operates in this fashion will require a foot valve to keep the liquid in the suction pipe to avoid having to re-prime the pump when it is stopped. We can calculate or we can measure NPSHA, let’s start with measuring NPSHA. The main measurement we need is the pressure close to the pump suction. But first a digression on what the pressure measurement we take will mean. What happens to the flow and pressure within the pump past the point of measurement. The next figure shows that the pressure drops considerably as the fluid enters the eye of the pump. This happens for two main reasons: the velocity as the fluid approaches the eye increases which decreases pressure also friction and turbulence further decreases pressure. The pressure can be low enough that the liquid will start to boil at this low pressure. What do you mean the liquid will boil at low pressure?

Figure 4 There are two ways to boil a liquid. One way is to increase the temperature while keeping the pressure constant until the temperature is high enough to produce vapor bubbles. In the next figure this is what happens if you take one point in the liquid phase and you move horizontally (that is at constant pressure) by increasing the temperature. Eventually you hit the vaporization line of the particular fluid and the fluid starts to boil or produce vapor bubbles. We do the same thing every day when we boil water in a pot. The other way to boil a liquid is to lower the pressure. If you keep the temperature constant and lower the pressure the liquid will also boil. In the next figure this is what happens if you take one point in the liquid phase and you move vertically (that is at constant temperature) by decreasing the pressure. Again you hit the vaporization line of the particular fluid and the fluid starts to boil or produce vapor bubbles.

Figure 5 If the pot were covered and you had a source of vacuum (see next figure) by lowering the pressure in the pot you would be able to make the water boil at a lower temperature. When the pressure is 7.5 psia or (14.7 – 7.5 = 7.2) or 7.2 psi less than the atmospheric pressure the water will boil at a temperature of 180 °F and when the pressure is 1.5 psia the water will boil at 120 °F. This is what happens at the pump suction when the pressure is low enough to make the fluid boil or vaporize. Check out this video It is not unusual for industrial processes to operate at temperatures that are close or higher than 120 F. Therefore if the temperature is high and the pressure drops as the fluid enters the pump, it will be easier to produce cavitation because the pressure drop produced by the pump will have to be smaller to match a higher vapor pressure. If cavitation is occurring or suspected, there are two possible solutions: to increase the pressure at the pump inlet or decrease the fluid temperature.

Figure 6 The pressure at which the liquid vaporizes is known as the vapor pressure and is always specified for a given temperature. If the temperature changes, the vapor pressure changes. See the pump glossary for vapor pressure values of different liquids. Why is vapor pressure an issue? If the pressure in the pump eye drops below the vapor pressure, cavitation will occur. Cavitation begins as the formation of vapor bubbles at the impeller eye due to low pressure. The bubbles form at the position of lowest pressure at the pump inlet (see Figure 4), which is just prior to the fluid being acted upon by the impeller vanes, they are then rapidly compressed. The compression of the vapor bubbles produces a small shock wave that impacts the impeller surface and pits away at the metal creating over time large eroded areas and subsequent failure.

| |||

| The sound of cavitation is very characteristic and resembles the sound of gravel in a concrete mixer. You can hear

characteristic noise of cavitation

|

|||

|

The formula for NPSHA based on a pressure measurement at the pump suction is:  [1]

[1]

where

where pGS: pressure in psig at the pump suction (this pressure can be negative zGS : is the difference between the gauge height and the pump suction, this is necessary to correct for an erroneous reading due to the gauge height. vS: the velocity of the liquid at the suction in ft/s pA: atmospheric pressure in the local environment pva: vapor pressure of the liquid at the operating temperature. SG: specific gravity of the liquid. If we are designing a system then it is not possible to measure the pump suction pressure and therefore we have to calculate it. The pressure head at the pump suction is given by:  [2]

where [2]

where HS: pressure head corresponding to the pressure measurement pGS z : the height between the free surface of the suction tank and the pump suction centerline. HF: the friction head loss in the suction line. HS is related to PGS by the static head relationship seen in the pump tutorial. If we replace the value of pGS in equation [3] into equation [1] and considering that there is no correction for pressure gauge height required the term zGS disappears, we then obtain:

Therefore to calculate NPSHA, we use equation[1] when we have an existing system and we can measure the pressure at the pump suction. And we use equation [4] when we are designing a pump system. Let’s try an example. The pump system used in the pump tutorial is a good start. We will use equation [4] to calculate the NPSHA. The value of z which is the suction static head is 15 feet. In the pump tutorial we calculated the friction loss in the suction to be 3.1 feet. The velocity head or term vs2/2g is often quite small, of the order of 1 foot or less and this is no exception so we will therefore neglect it. The atmospheric pressure is 14.7 psia. The vapor pressure for water at 60F is 0.5 psia. Values for vapor pressure of other fluids at various temperatures is available in the pump glossary. The specific gravity of water is 1.0.

The value of NPSHA is then: |